Thick plate flame cutting standards

1. Material requirements

First check whether the quality and various indicators meet the specified requirements and whether the various information on the steel plate is correct.

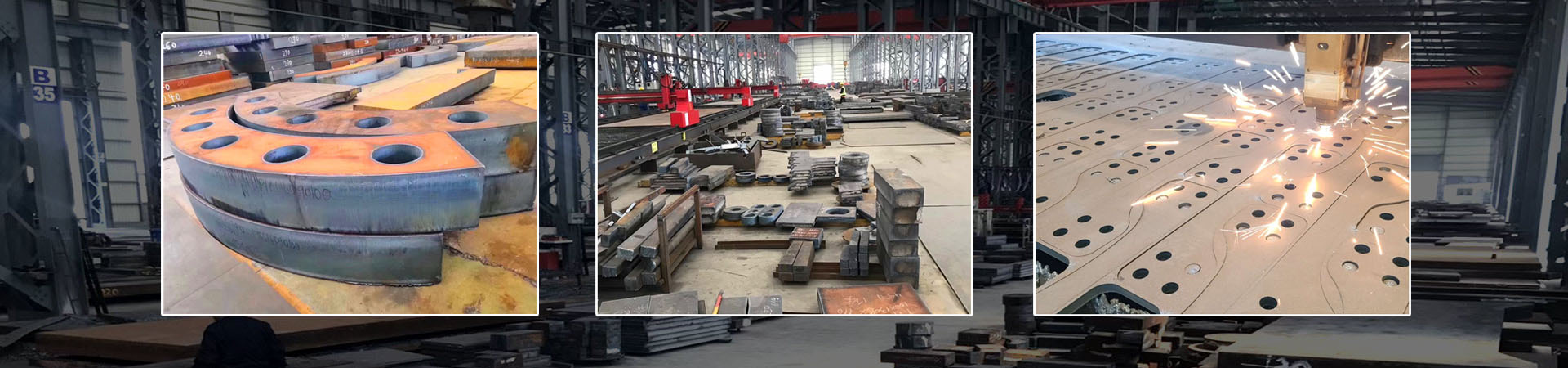

2. Cutting operation process

(1) Before cutting, the steel plate must be cleaned.

(2) During automatic cutting, after the steel plate is placed on the platform, the distance between both ends and the guide rail should be within 5mm.

(3) During semi-automatic cutting, the guide rail should be placed on the flat surface of the steel plate first, and then the cutting machine.

(4) The side with the cutting torch faces the operator. Select the cutting nozzle according to the thickness of the steel plate, and adjust the cutting straightness and speed, as well as cutting parameters, process parameters, etc.

(5) The cutting torch should move at a constant speed, and the distance between the tip of the flame center and the surface of the cut piece should be 2 to 5mm.

(6) According to the thickness of the steel plate, the airflow length of the preheating flame should exceed one-third of the thickness of the workpiece, and the cutting nozzle and the surface of the workpiece should be at a certain angle to allow the edges of the part to be heated evenly.

(7) Observe factors affecting cutting quality at any time.

3. Inspection indicators of thermally cut parts: Whether there are cracks, slag inclusions and other defects in appearance. When the workpiece is cut, the name, number and other information should be indicated, including component specifications, component material, etc.

Shangyi Steel has sufficient resources, high precision of finished products, smooth and neat cuts, and small processing allowance. It is the choice for major machinery factories to save trouble, materials and money in purchasing!